Galvanized coils and strips are used in a wide range of applications, such as automobile manufacturing, electrical products, rolling stock, aviation, precision instruments, food cans, etc.

Galvanized coil plate is the abbreviation of ordinary carbon structural steel cold-rolled plate, also known as cold-rolled plate, commonly known as cold plate, sometimes mistakenly spelled as cold-rolled plate. Cold plate is made of ordinary carbon structural steel hot-rolled steel strip, which is further cold-rolled into a steel plate with a thickness of less than 4mm. Because it is rolled at room temperature and no iron oxide is produced, the cold plate has good surface quality, high dimensional accuracy, and after annealing treatment, its mechanical properties and process performance are better than those of hot-rolled thin steel plates.

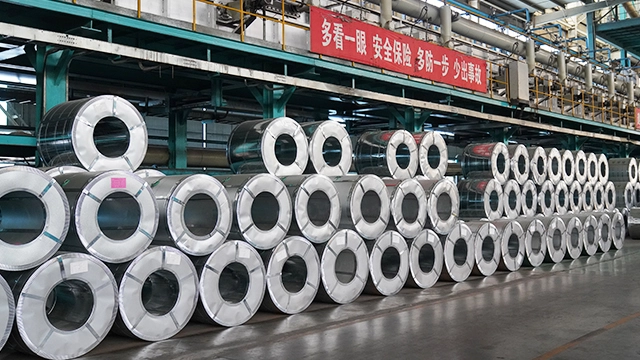

Galvanized sheets and coils are made from hot-rolled coils rolled at room temperature at recrystallization temperature, including plates and coils, and can be produced by many domestic steel plants such as Baosteel, Wuhan Iron and Steel, and Anshan Iron and Steel. Among them, those delivered in plates are called steel plates, also known as box plates or flat plates; those that are very long and delivered in rolls are called steel strips, also called coiled plates.

Definition of galvanized sheet and coil

It is rolling under recrystallization, but it is generally understood as rolling the material using room temperature rolling. Aluminum cold rolling is divided into plate rolling and foil rolling. The thickness of 0.15~ and above is called plate, and the thickness of 0.15~ and below is called foil. Europe and the United States mostly use 3 to 6 continuous rolling mills as cold rolling equipment.

Production Process

Galvanized coils are not heated during the production process, so there are no pitting, iron oxide and other defects that often occur in hot rolling, and the surface quality is good and the finish is high. Therefore, the dimensional accuracy of cold-rolled products is high, and the performance and structure of the products can meet some special requirements, such as electromagnetic properties, deep drawing properties, etc.